- Electrical Contacts

Electrical Contacts

- Carbon Brushes

Carbon Brushes : Brush Reference

- Control Coils

Control Coils

- Other Contactor Parts

- More

- Search

- Auxiliary Contacts

Auxiliary Contacts

- Shunts

Shunts

- Springs

Springs

- AC Contactors & Starters

AC Contactors & Starters

- DC Contactors

DC Contactors

- Drives

Drives

- Fuses

By: Greg Carter | G+

Brushed vs. Brushless Electric Motor Requirements

An introduction for Electrical Distributors

In this discussion we’re going to look more closely at Carbon Brushes and learn why motor replacement parts continue to be in demand.

In this discussion we’re going to look more closely at Carbon Brushes and learn why motor replacement parts continue to be in demand.

Sometimes electric motors and machines are older, but working fine.

So, finding a reliable source for electric motor brush replacement parts can save your customer time and money in lost productivity when doing maintenance or repair that requires equipment to be offline.

A carbon brush supplier who stocks all major brands of motor control replacement parts can “save your sale” when faced with OEM backorders due to unavailable parts at the factory.

First, to help your customer choose the right carbon for electric motors , it’s helpful to know what a motor brush is and how it works.

What Are the Needs of Brushed vs. Brushless Motors?

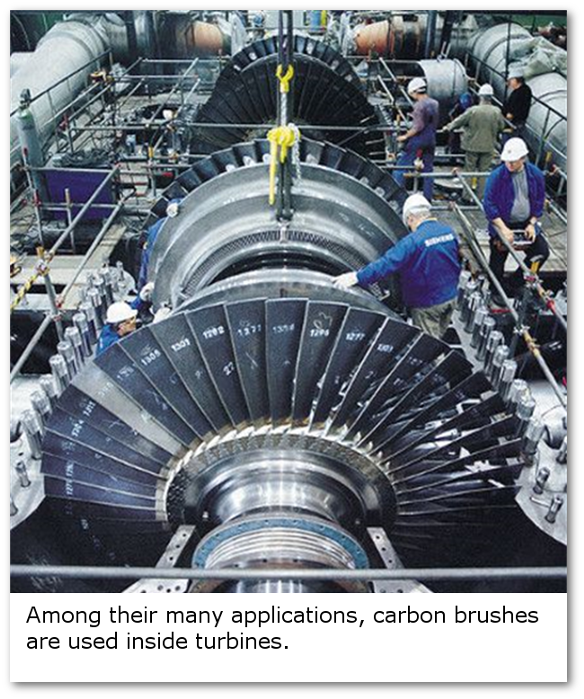

Brushes in motors and generators conduct electricity. They pass electric current between the stationary and rotating parts of the motor. Brushless motors have none of these current-carrying carbon brushes. Brushed motors should be routinely inspected for carbon brush wear due to physical contact during commutation.

What Happens if Carbon Brushes are Worn?

You’ll know it’s time to check and possibly replace carbon brushes when the top of the brush has receded into the brushholder. Also, if there are signs of breakage, crumbling, or burning, the brush needs replacing.

The life of a carbon brush is dependent on several psychical factors including running conditions, alignment of brush and pressure settings, environmental factors including temperature, contamination and humidity.

Routine visual inspections for common problems can help identify these conditions before they become an issue. If any of the following occur, you should contact an electrician to have your motor inspected:- Excessive sparking from the commutator when in use

- Decrease in power from the motor

- Motor ceases to operate

I Need Help Selecting a Carbon Brush for my Electric Motor

Sometimes you’ll need help choosing the right carbon brush. That’s where a “Knowledge Based” specialty supplier can assist. Repco’s electric motor replacement parts catalogs contain true-to-size illustrations of carbon brushes, showing you what OEM replacement parts you need. The guide spans 35 motor manufacturers.

Finding a reliable source for electric motor brush replacement parts can save time and money when doing maintenance or motor repair. Keeping your customers’ facility production online and helping you earn and keep their business is where REPCO can help.

Learn more about Carbon Brushes in the Repco BlogInternational: 856-762-0172

Domestic: 800-822-9190

Literature Request Or Download

Click here to download or browse our Electrical Contact, Carbon Brush, or Control Coil catalogs online.

Repco

100 Sonwil Drive

Buffalo NY 14225Repco Quick Contact

We are excited to announce that REPCO has merged with USA Industrials.

For all inquiries, please contact us at service@usaindustrials.com or give us a call at 800-822-9190.

We appreciate your understanding and look forward to serving you better with our expanded capabilities.

- Carbon Brushes